Industries

Key Sectors We Serve

Aerospace & Automotive

Advanced materials. Intelligent control. Additive precision.

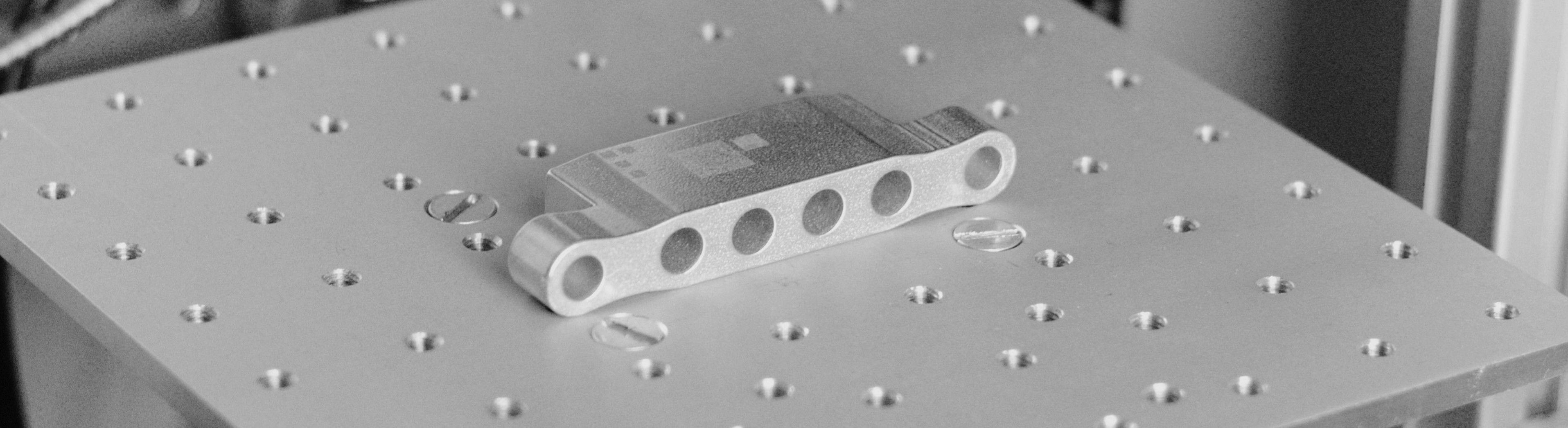

We support leading research institutes, equipment builders, system integrators and OEMs in pioneering the industrialization of Functionally-Graded Additive Manufacturing (FGAM) for high-performance components – such as turbine blades and propulsion systems. To this point, we contributed to the development of a robot-compatible laser measurement head enabling real-time, atom-level quality assurance via laser-induced plasma spectroscopy (LIBS) in L-DED processes. FGAM minimizes post-processing, enables on-demand material allocation, and avoids waste by depositing only what is needed – exactly where it’s needed. This not only saves resources and time, but also reduces unnecessary material movements, overprocessing, and rework.

Beyond aerospace, we also assist medtech innovators in the development of gradient implant production, with custom 3D process monitoring and data modeling for regulatory-compliant process control. The objective: personalized implants – where mechanical and chemical properties vary along the geometry – a field where FGAM and intelligent QA can unlock new regulatory and performance frontiers.

Semiconductor & Power Electronics

In the rapidly expanding fields of e-mobility and renewable energy, power-electronic semiconductors play a decisive role. We support this domain across the entire value chain - from materials and substrates to device packaging and system integration - by bringing together advanced laser technologies, digital-twin approaches, and methodical, automated analytics.

Our focus lies in enabling high-precision, intelligent, and adaptive manufacturing environments, where every process step is continuously monitored and optimized. This creates robust production lines that can handle the complexity of wide-bandgap materials such as silicon carbide (SiC), ensuring performance and scalability at industrial level.

Why SiC Matters

SiC has emerged as a key enabler for high-efficiency power conversion. Its wide bandgap, high thermal conductivity, and breakdown field strength allow for compact devices that can switch large currents with minimal losses. This is critical in applications like EV powertrains, ultra-fast charging stations, and wind or solar inverters, where efficiency, reliability, and compactness directly translate into range, cost savings, and sustainability.

By reducing switching and conduction losses, SiC technology makes it possible to shrink cooling systems, improve system-level efficiency, and accelerate the global transition toward electrified mobility and renewable energy integration. Vision

SiC devices form the backbone of efficient energy conversion, supporting cleaner transport, more reliable grids, and the large-scale deployment of renewable energy. We see semiconductor and power electronics manufacturing moving toward fully adaptive production systems, where laser-based processes and continuous data-stream management ensure optimal quality and throughput.

Information Technology

Light-driven data processing & optical efficiency by design.

We develop advanced photonic systems that shift data operations upstream – away from power-hungry electronics and into the optical domain.

Our approach: spectral processing in-light.

We design signal chains that let light – not transducers – do the heavy lifting: Spectrally rich signals are filtered, interpreted, or encoded physically before any electronic conversion takes place.

Applications include:

- Pre-electronic noise rejection and data reduction in laser-based manufacturing

- Inline optical feature extraction in spectroscopic QA

- Energy-efficient, high-throughput data analysis in demanding production environments

By avoiding the early transduction of uninformative signal components, we prevent:

- amplification of noise

- excessive digital processing

- and the resulting electronic waste stream that burdens systems with heat, cost, and inefficiency.

Optical systems do not “run hot”. They follow the laws of optics and quantum mechanics, enabling passive, high-speed interactions – with minimal energy and latency input.